- Products

Honeycomb Core

Aluminum & AramidCrash Test Barriers

Full Range of BarriersEnergy Absorbers

For Crash Test TechnologySpecialty Products

Distribution Partners - About Us

About Argosy

ESG

HSE

- Our Business

Business Overview

Services

- News

Quote required

Quote required

Quote required

Quote required

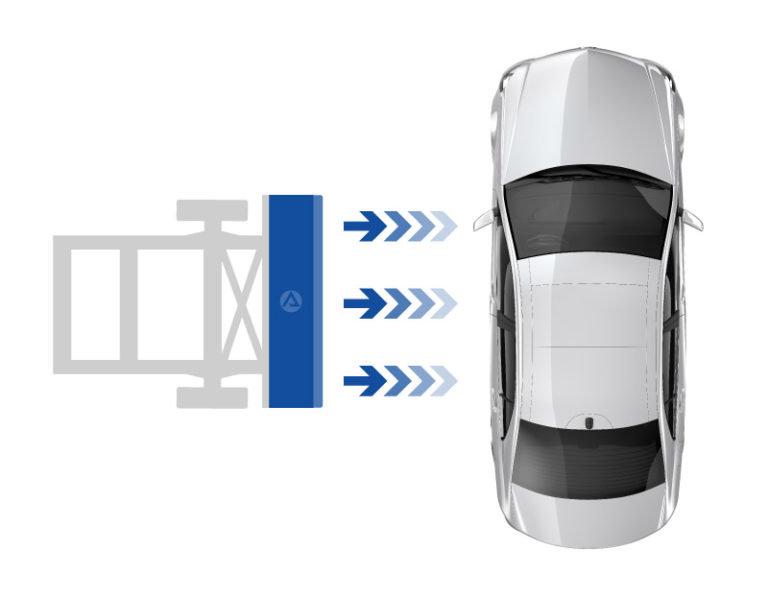

Based on Aluminum Honeycomb technology, the MDB-R95 barrier (EEVC WG13) is used by car manufacturers and test laboratories worldwide for the assessment of motor vehicle passenger protection in side impact collisions.

The side-impact test consists of a 950 kg trolley impact on the driver’s side of the test vehicle. The trolley is equipped with an MDB-R95 barrier, which aims at simulating the front of the impacting vehicle. The impact speed is defined according to the test specifications. ATD’s dummies are used to evaluate the injuries in this type of crash.

The side barrier consists of 6 joined zones with a total quantity of kinetic energy to be absorbed by the frontal barrier is between 42 and 48 kJ (EEVC-R95 amendment 3).

Adhesive:

A complete testing procedure for certification of aluminum honeycomb is performed in-house according to EEVCC-R95 Amendment 3. The aluminum honeycomb blocks are processed such that the force deflection-curve when statically crushed is within the corridors defined for each of the six blocks.

The MDB-EEVC-R95 barrier is certified for occupant protections:

The MDB-EEVC-R95 barrier is certified for NCAP tests:

The AXAC MDB-R95 Advanced 2000 side impact deformable barrier is manufactured according to EEVC WG13’s recommendation from November 2001, in compliance with ECE R95 Amendment 3 and 96/27/EC.

AXAC has an approved IS09001 Quality Management System, demonstrating a commitment to supplying customers with the highest quality products and services.

Quote required

Quote required

Quote required

Quote required

Delivering Performance Through Global Collaboration.

Global supplier of specialty materials and services that solve challenging technical and business problems.