- Products

Honeycomb Core

Aluminum & AramidCrash Test Barriers

Full Range of BarriersEnergy Absorbers

For Crash Test TechnologySpecialty Products

Distribution Partners - About Us

About Argosy

ESG

HSE

- Our Business

Business Overview

Services

- News

Quote required

Quote required

Quote required

Quote required

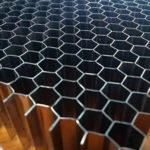

ARGOSY 3000 Series Aluminum Honeycomb is a lightweight honeycomb core that offers superior strength and corrosion resistance to meet a broad range of demanding applications. It is a high performance, low-cost structural core material that is perfect for architectural, transportation, marine, and other industrial applications.

ARGOSY 3000 Series Aluminum Honeycomb is utilized in a wide range of applications where: Lightweight, High flex strength, Corrosion-resistant, low-cost core panels are desired. These include:

When ordering, please specify material type using the following format: Example 5.2 1/4 -N-E

| PRODUCT | DENSITY | CELL SIZE | PERFORATED OR NON-PERFORATED | EXPANDED or UNEXPANDED |

|---|---|---|---|---|

| Aluminum Honeycomb | 5.2 | 1/4 | P or N | E or U |

| STANDARD | MAXIMUM | TOLERANCE | |

|---|---|---|---|

| Ribbon (L) | 48 inches (1220 mm) | 72 inches | (1829 mm) | +2.0/-0.0 inches | +50.8 / -0.0 mm |

| Transverse (W) | 96 inches (2440 mm) | 354 inches (9000 mm) | +4.0 / -0.0 inches (+101.6 / -0.0 mm) |

| Thickness (T) Block | N/A | 34.5 inches (876 mm) | +1.0 / -1.0 inches (+25.4/ -25.4 mm) |

| Thickness (T) Slice | Up to 4 inches (102mm) T | Up to 4 inches (102mm) T | ±0.004- (±0.1 mm) |

| Expanded Panel | Over 4 inches (102mm) T | Over 4 inches (102mm) T | ±0.062- (±1.575 mm) |

| Density | See Product Availability Chart | See Product Availability Chart | ± 15% |

| Cell Size | See Product Availability Chart | See Product Availability Chart | ± 15% |

| ALLOY | NOMINAL CELL SIZE | NOMINAL DENSITY PCF | NOMINAL FOIL THICKNESS INCHES | NOMINAL FOIL THICKNESS MICRONS |

|---|---|---|---|---|

| 3000 | 3/16 | 4.4 | .00185 | 47 |

| 3000 | 1/4 | 3.4 | .00185 | 47 |

| 3000 | 1/4 | 3.4 | .00285 | 72 |

| 3000 | 3/8 | 2.3 | .00185 | 47 |

| 3000 | 3/8 | 3.6 | .00285 | 72 |

| 3000 | 1/2 | 1.7 | .00185 | 47 |

| 3000 | 1/2 | 2.6 | .00285 | 72 |

| 3000 | 3/4 | 1.2 | .00185 | 47 |

| 3000 | 3/4 | 1.8 | .00285 | 72 |

| 3000 | 1 | 1.3 | .00285 | 72 |

| CELL SIZE (INCHES) / DENSITY (LBS) | STABILIZED COMPRESSION | STRENGTH "L DIRECTION" (MPa) | MODULUS "L DIRECTION" (PSI) | STRENGTH "W DIRECTION" (MPa) | MODULUS "W DIRECTION" (PSI) |

|---|---|---|---|---|---|

| 1/4 Inches | Density 3.4 | 2.00 MPa | 543 PSI | 1.60 | 258 | 0.90 | 128 |

| 1/4 Inches | Density 5.2 | 2.80 MPa | 998 PSI | 2.20 | 438 | 1.30 | 221 |

| 3/8 Inches | Density 2.3 | 1.11 MPa | 242 PSI | 0.86 | 189 | 0.59 | 88 |

| 3/8 Inches | Density 3.6 | 1.56 MPa | 632 PSI | 1.20 | 283 | 0.82 | 144 |

| 1/2 Inches | Density 1.7 | 0.65 MPa | 94 PSI | 0.7 | 102 | 0.4 | 58 |

| 1/2 Inches | Density 2.6 | 0.86 MPa | 274 PSI | 0.80 | 222 | 0.55 | 99 |

| 3/4 Inches | Density 1.2 | 0.35 MPa | 51 PSI | 0.4 | 58 | 0.3 | 44 |

| 3/4 Inches | Density 1.8 | 0.48 MPa | 163 PSI | 0.48 | 111 | 0.35 | 54 |

| 1 Inches | Density 1.3 | 0.35 MPa | 51 PSI | 0.4 | 58 | 0.3 | 44 |

*Information contained above is typical only and should be verified for any specific applications

Quote required

Quote required

Quote required

Quote required

Delivering Performance Through Global Collaboration.

Global supplier of specialty materials and services that solve challenging technical and business problems.