The NHTSA Frontal Mobile Deformable Barrier Face v2013 deformable barrier is an assembly of two layers of deformable aluminium honeycomb core. Both deformable cores (300 mm thick in the impact direction T), designed to provide a constant load in depth, adhesively bonded together with different aluminium sheets forming a ready to use deformable barrier to be fixed on a moving trolley.

A complete testing procedure for certification of aluminum honeycomb is performed in-house according to Frontal Oblique and Small overlap Impact Crashworthiness Evaluation, NHTSA Test procedure, July 2015 and in accordance with the procedure defined in NHTSA TP-214D. The aluminum honeycomb blocks are processed such that the force deflection-curve when statically crushed is within the corridors defined for each of the 2 blocks.

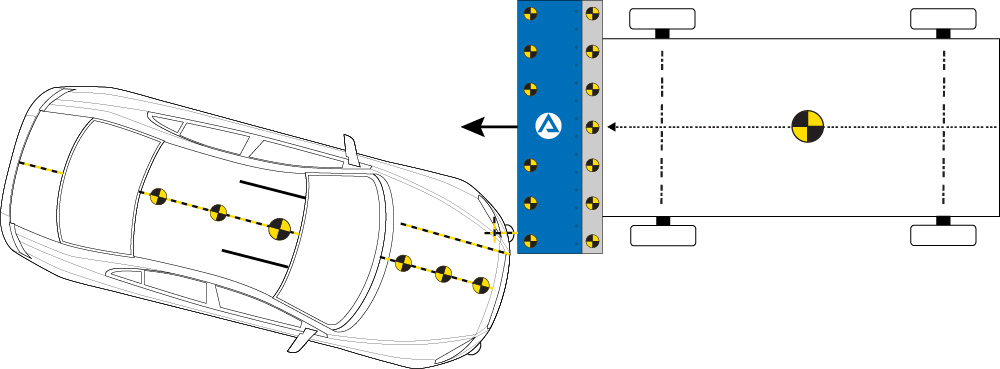

The NHTSA O-MDB barrier is designed for Frontal Oblique and Small overlap Impact Crashworthiness Evaluation, NHTSA Test procedure, July 2015.

The AXAC O-MDB Frontal Mobile Deformable Barrier are manufactured according to NTHSA Frontal Mobile Deformable Barrier Face specification v2013 in compliance with Research Moving Deformable Barrier RMDB v2015 and Frontal Oblique and Small overlap Impact Crashworthiness Evaluation, NHTSA Test procedure, July 2015.